The arrival of the new 3D printer from 3D Systems means the beginning of a "mechatronics" era for SISSA. SISSA is an international training school located in Trieste, Italy. The school’s focus is on forward-looking scientific research plans.

They use 3D Systems' 3D printers to establish a new laboratory, enabling SISSA researchers to self-sufficiently design and mechanical structures.

With this sophisticated equipment, including a new generation of ProJet3510 multi-nozzle 3D printer, and laboratory expertise, scientists will no longer have technical limitations, and can do their work more creatively and develop technologies that are more suitable for their needs. . Marco Gigante, an engineer responsible for 3D design in the SISSA laboratory, commented, "We have endless possibilities for creativity."

This laboratory, headed by Mathew Diamond, a scientist from SISSA, combines the field of mechanics, electronics and all research programs within SISSA, making it an almost unique center among scientific research institutions in Italy. Fabrizio Manzino, who is in charge of laboratory software development, explained, "Our scientists rely on sophisticated and accurate electronic control system experimental equipment for many experiments."

"The scientists in this study will come and use the experimental equipment with us until we are ready to set up all the parts."

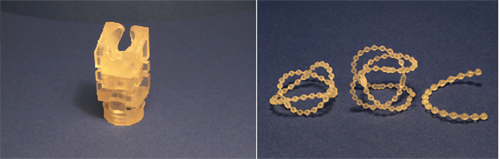

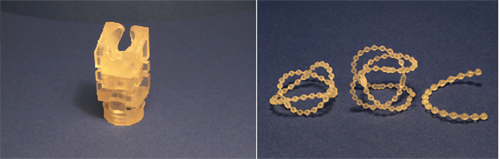

Today, this event will be even more creative: Erik Zorzin, responsible for electronics, explained, "This new printer has a high resolution with a layer thickness of 16 microns-allowing us to develop highly complex objects and monolithic components; some things Cannot be made by traditional production methods".

Manzino added that before the arrival of ProJet 3510, the process of making sophisticated mechanical parts was very complicated and costly.

"We have to do a little inaccurate mold and approximate work. Usually, we can't build all objects in one block. We have to make single model parts and then assemble them."

The laboratory is equipped with other mechanical tools, such as a CNC machine used to manufacture the necessary circuits for controlling mechatronics devices and cutting other metal objects.

Software development is also the basic work of the laboratory for design (CAD/CAM) and control functions for experimental settings. Zorzin explained, "New laboratories and new machines will be added gradually, opening up the possibility of SISSA research.

In the past, we had to adapt the experiment to the existing technology, but now we can adapt the technology to the experiment, and therefore can adapt to the needs of research".

![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158