![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158

![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158

PRODUCT LIST

|

|

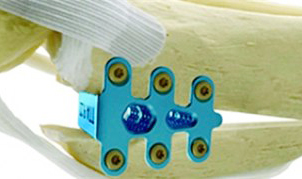

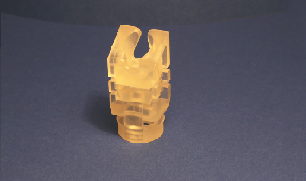

1. Selective laser melting equipment SLM 125 can print high-quality metal parts based on 3D-CAD data. The equipment combines compactness, economy and high precision, and is mainly suitable for small batch processing, such as research and development. 2. The patented two-way powder spreading technology has achieved the fastest forming speed in the same type of equipment, and the gas circulation filtration technology has not only been patented, but also presented the design concept of safe operation. The inert gas stream can achieve the most ideal process characteristics even when the minimum consumption is adjusted. 3. SLM 125 can be equipped with a fully open software for reading CAD/STL data or slice data, allowing users to customize processing parameters according to their needs to achieve personalized processing. Printing materials can choose stainless steel, tool steel, cobalt-chromium alloy, nickel-based alloy, aluminum alloy, titanium and its alloys, etc. The compact structure of the equipment and a small number of powder transfer components ensure quick and easy powder replacement. In addition, a large number of options and extended functions enable the system to adapt to the individual needs of various customers. 4. The sieving equipment PSM can be used with SLM 125 to achieve the best effect. During the sieving process, large particles of powder will be sifted out and separated into a storage bottle. The reusable powder that reaches the particle size will be transferred to the storage container and can be reused directly. |

Copyright © Shenzhen Airboat Technology Co., Ltd. All rights reserved 【Backstage management】

Chinese

Chinese