![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158

![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158

PRODUCT LIST

First of all, what is Maggy?

Maggy is a small wearable device that helps you maintain social distance while maintaining privacy. When the distance between users is too small, it will sound and vibrate notifications.

Maggy relies on the combination of small wearable devices and optional mobile applications for many reasons. On the one hand, it has accuracy—standard smartphone Bluetooth chips have an accuracy of up to 1 to 2 meters, while Maggy contains the most advanced Bluetooth 5.1 and 5.2 chips, which are characterized by an accuracy of about 10 to 15 cm.

On the other hand, wearable devices have the advantage of security-no registration is required, and no user data needs to be saved. As long as you give this device to employees or visitors, they can use it at any time. Finally, Maggy also provides a rechargeable battery, the battery life can be used continuously for five days. Some leading companies and multinational companies in Belgium have expressed great interest in this solution.

How to release such a complex device in such a short time?

After the initial product release, Maggy was overwhelmed by a large amount of demand (45K+ pieces), and it obviously took time to increase the production of custom PCBs and other components. Therefore, through short-term testing, they can effectively organize short-term testing to narrow the gap.

In order to do this, Maggy decided to rely on 3D printing, more specifically SLS (Selective Laser Sintering). Among all the available 3D printing technologies, SLS has proven itself to be a true promoter on several levels-design freedom, production freedom, complex internal geometries, smooth surface finishes, fine and robust parts... these Only some of the functions realized by this technology.

However, the mainstream SLS technology, although it can produce high-quality components, is still quite expensive and may not be acceptable to smaller start-ups or consumers. Therefore, Maggy is looking for a partner who can support them in establishing a quality and affordable way for small batch production runs. Maggy found PrintPlace.

PrintPlace: Friendly neighborhood 3D printing started

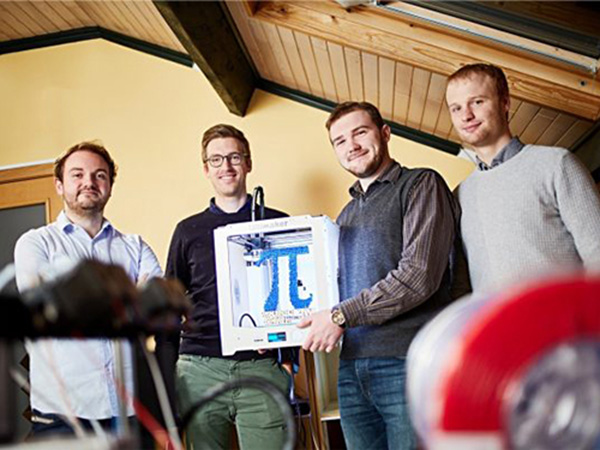

PrintPlace is a Belgian start-up company founded by four enthusiastic engineers who are passionate about 3D printing, hoping to make this technology more accessible by focusing on specific applications, and this technology is economical Way to achieve. The price is affordable because PrintPlace relies on the use of smaller "desktop 3D printers", which can be used in a more efficient manner than their large industrial brethren.

Qualitative, because PrintPlace not only masters the art of 3D modeling and 3D printing, but also provides personal guidance during the development of objects or products, whether it is a prototype, a series of production, mass production, or even "large Scale customization".

It is important to understand that PrintPlace is not any old 3D printing service-it is a community-friendly startup that takes time to take your project from a digital concept to a physical product. They treat every project equally, whether it is a large project or a small project, whether it is to the organization or the individual. They create together, think together, and propose the best solution. They are problem solving experts and have expertise in various industries.

Maggy, PrintPlace and Sinterit join forces

Maggy has high requirements in terms of dimensional accuracy and appearance. They definitely want to provide customers with high-end products in a fast and affordable way. Therefore, Maggy and PrintPlace agreed to organize a small batch production through cutting-edge desktop SLS technology, miniaturized version of industrial-grade SLS, and novel production methods.

Only when applied to the right application and the right volume, this technology provides unparalleled results in terms of dimensional accuracy, surface finish and part price. One of the applications is small batch production.

To ensure correct production for the first time, PrintPlace works closely with Sinterit, a leader in desktop SLS technology, which owns the LISA SLS 3D printer ecosystem. PrintPlace and Sinterit considered every step of the production process—Sinterit provided support in optimizing LISA Pro build preparation, ideal machine operation, machine maintenance and post-processing.

The results of the cooperation between Maggy, PrintPlace and Sinterit are self-evident:

Copyright © Shenzhen Airboat Technology Co., Ltd. All rights reserved 【Backstage management】