![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158

![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158

PRODUCT LIST

|

|

Geomagic® Freeform® overview

Geomagic® Freeform® is the only multi-layer image representation and touch-enabled digital modeling system. It uses organic shapes and designs to provide great convenience for detailed and fast 3D modeling. It can be integrated into a traditional CAD workflow or sent directly to prototyping and manufacturing. Utilizing the tandem connection with the Sensable® Phantom® tactile device, Geomagic Freeform provides you with full use of the advantages of the digital workflow to speed up the manual modeling and enhance its feel. Freeform is a key component of many digital manufacturing and design processes, and it can also be used as a single source for a complete workflow from the initial design to the final model that can be produced. Models created in Freeform can be manufactured using rapid prototyping, CNC machining, rapid prototyping manufacturing, or other traditional production workflows. Geomagic Freeform's versatility and rich tool set make it an important part of today's digital design process and a complete solution from concept to production-ready model. Geomagic Freeform is the only software that allows users to choose the appropriate modeling image representation according to their requirements. In a single model, designers can switch between voxel (digital clay), NURBS, subdivision surface, and polygon mesh modeling to give full play to the advantages of 3D modeling. The latest version of Freeform also comes with advanced texture processing functions. Designers now have the ability to create and apply richly detailed, size-controllable textures and patterns in less than a minute, and these patterns can be used immediately for prototyping and production. We also provide Geomagic® Freeform® Plus version, which includes all the tools in Geomagic Freeform, in addition to mold making and manufacturing tools, NURBS surface treatment, solid design tools, and CAD part interoperability. Geomagic Freeform provides customers with the tools they need to enhance productivity, improve design quality, and accelerate time to market. Freeform's rich tool set can be used in the design of styling products in various industries-consumer products, medical equipment, footwear, home decoration and other industries-and its dedicated functions enable users to analyze potential problems as early as the design process, Identify and resolve. Therefore, you can easily maintain process control while avoiding accidents in the production process. Freeform and Freeform Plus can be used with Sensable® Phantom Omni® or Sensable® Phantom® Desktop™ tactile devices, respectively. These tactile input devices provide force feedback to your hands and accurately position them in 3D space, allowing you to use functions such as pushing, pulling, engraving, dragging, and smoothing the model, just like you are doing manual modeling. Toy manufacturing

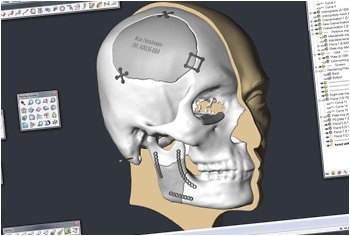

Freeform enables toy makers to have the best of both worlds. They can create original and carefully designed products that are different from other toy makers, while ensuring smooth production preparation and processing. With Freeform, it is very simple to quickly merge input from production companies, designers, and manufacturing engineers. Medical implants and surgery simulation Geomagic Freeform provides medical professionals and equipment manufacturers with a way to quickly create patient-specific equipment and surgical guides, custom repairs and supporting orthotics. Designers can import CT and 3D scan data into Freeform, and then create and operate accurate models generated according to the recording time to ensure patient safety. Consumer product manufacturing Using the versatility of Freeform, product designers can quickly transition from a single product design concept to multiple design iterations. They can even incorporate 3D scan data of existing products into new product designs. Successful designs can be easily fine-tuned using Freeform's intuitive interface and quickly prepared for manufacturing.   |

Copyright © Shenzhen Airboat Technology Co., Ltd. All rights reserved 【Backstage management】