![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158

![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158

PRODUCT LIST

|

|

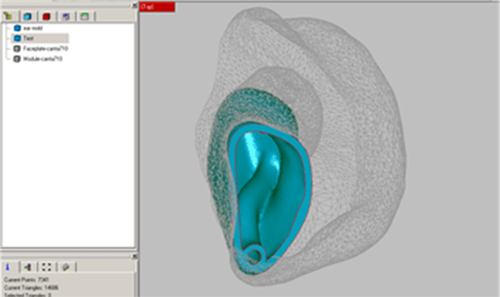

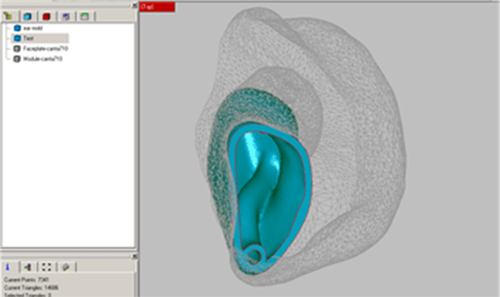

Geomagic Studio® reverse engineering software

Geomagic Studio® is a complete tool set that converts 3D scan data into high-precision surfaces, polygons and general CAD models. For the key components in a series of manufacturing workflows, Geomagic Studio provides the industry's most powerful point cloud, mesh editing functions and advanced surface processing capabilities, while maintaining its smart and easy-to-use features. In addition to the precise 3D data processing functions of Geomagic Studio, it also integrates a large number of automation tools, all of which enable users to significantly shorten time and reduce labor costs while producing the highest quality models. For reverse engineering, product design, rapid prototyping, analysis and export CAD, Geomagic Studio is the core 3D model creation tool. With a command-line-driven software version and a new Python scripting environment, Geomagic Studio combines high speed and its level of customization to run its powerful 3D data processing capabilities. Geomagic Studio also simplifies the design process by seamlessly transferring parametric models to several major CAD software packages: CATIA®, Autodesk® Inventor®, CREO® Elements/Pro™ (Pro/ENGINEER™) and SolidWorks®. Automobile design and manufacturing

Aerospace

Heavy equipment manufacturing

Medical equipment and equipment

|

Copyright © Shenzhen Airboat Technology Co., Ltd. All rights reserved 【Backstage management】