SIU SYSTEM first realized the use of ProJet 3500 CPXMax to provide Armenian jewelry clients

The exquisite craftsmanship and expertise of Armenian jewelers for hundreds of years are well known. You can even say that if there is only one industry that can define Armenia, it is jewelry. Back in the Ottoman Empire, Armenia was monopolized by Sudanese jewelers and monopolized it, only passed on to its family members from generation to generation. As a result, the charm of beautiful jewelry can only be kept in Armenia's phone card for a long time.

With this artistic tradition, Sudanese jewelers continue to uphold the correct methods they have verified. However, this new industrial technology, 3D printing, began to intervene to complement and create the primary technology perfected by the Armenian jewelers of all generations.

SIU System is a trusted 3D Systems distributor. They recently sold the first ProJet 3500 CPXMax 3D printer in Armenia to the VS Chakhoyan jeweler, and it is already assisting the jeweler to solve its workflow.

Our customers have an increasing trend in new customer data. In order to meet their needs, make them satisfied with the quality of the product, and still retain the core of their traditional workflow, our customer purchased CPXMax, the implementation of SIU System Chief Ashkhen Ovsepyan said. "Now the customer can not only continue to maintain, but also more easily increase his customer base."

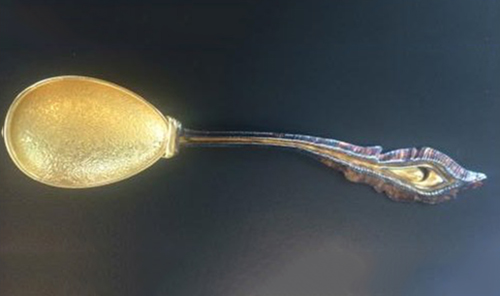

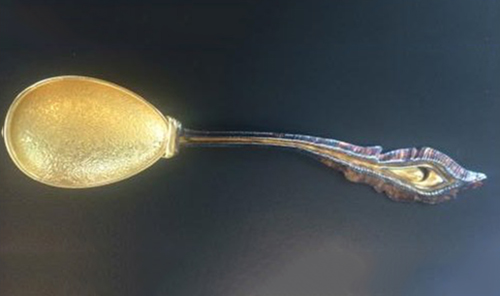

This high-performance ProJet 3500 CPXMax prints amazingly. Jewelers and aerospace, mechanical, and automotive engineers can use the characteristics of RealWax materials comparable to traditional wax castings and precision casting to increase their production. . More importantly, they can greatly increase the speed of production while achieving an unparalleled level of product feature details and appearance quality.

Prior to CPXMax, VS Chakhoyan jewelry used competitive technology, and several additional steps had to be used just to obtain the wax model. But just a few months after the arrival of CPXMax, they have been able to produce many high-quality wax molds directly, quickly, and simply at once. Ashkhen said, “They are really satisfied with the high quality and efficiency presented by 3D printing.” In fact, our customers cannot imagine without CPXMax's assistance in the jewelry manufacturing process. He is even looking for a new way to use 3D printing and use it in his business, and even thinking of adding more machines.

Regarding the SIU System, this plan is a great opportunity to implement new technologies, while also maintaining a set of methods that are the core of the customer’s business. In the case of Armenian jewellery, this means that in an extremely competitive world, assisting in the promotion of a long-standing tradition of exquisite craftsmanship can keep practitioners competitive.

![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158