We are very proud that our advanced manufacturing technologies, such as lasers, micro CNC machining and 3D printers, are used to promote research and research on new equipment that improves the quality of life. "Mike Davis, Vice President of Operations at Potomac Photonics, said.

Stem cells have great potential in medical research because of their ability to transform specific cells. One day they can provide renewable resources that can replace cells for those who need organ transplantation or who are suffering from diseases, such as those with Parkinson's, type 1 diabetes and cardiovascular disease.

In order to achieve these goals, Boston University found that they needed a microenvironment controlled by cells to manage and estimate how stem cells interact with each other through direct contact and cell secretion factors. The microenvironment requires high-precision, solid parts with fine details to make, so the researchers asked Potomac Photonics and 3D printing companies for assistance.

Potomac Photonics is a leader in micro molding, dedicated to helping customers develop micro products and put them into the local market, such as medical equipment, electronic products, aerospace products and automation products. Potomac's high-tech equipment, located in Lanham, Maryland, is ISO 9001:2008 and ISO 13485:2003 certified.

For this project, in order to obtain the high-resolution output required by the university, Potomac Photonics chose to use the ProJet 3500 HDMax 3D printer from 3D Systems. The ProJet 3500 series printers use UV-curable plastic jets on the build platform, and the fineness of the part size can reach an error of only 0.001-0.002 inches per inch. The printing system supports more materials, and can produce products with high strength, flexibility and ABS-like performance according to the requirements of the university.

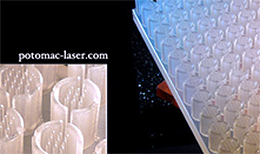

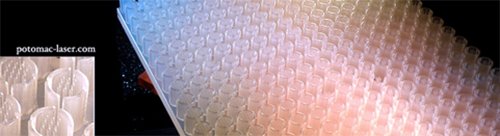

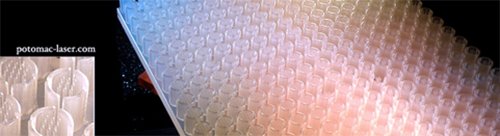

For the stem cell microenvironment project of the University of Boston, Potomac Photonics has produced a highly accurate template-a special pattern that allows stem cells to grow in a specially arranged relationship with each other. They have prepared several different templates, and researchers at Boston University hope to determine how the relative positions and how close the stem cells are to affect their differentiation efficiency and differentiate their offspring.

This work carried out by Potomac Photonics’ educational production plan shows another unique way: 3D printing and advanced micro-molding technology are the pioneers of innovative applications and products. Mike Davis, vice president of operations at Potomac Photonics, said, "We are very proud that our advanced manufacturing technologies, such as lasers, micro CNC machining and 3D printers, are used to promote research and research on new equipment that improves the quality of life."

![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158