3D printing SLS technology brings high detail and speed to C.ideas company

Mike Littrell, president of C.ideas, said that the quality is very good, and I cannot do without this machine in this process." For me, this all-digital, high-resolution, high-speed machine is definitely the next reasonable one in this process. Direction to achieve stunning quality appearance and excellent details.

C.ideas rapid prototyping center, during 14 years of operation, has a complete service for the well-known plastic extrusion process (FDM) and PolyJet house in the industry. However, as the company continues to grow and get help from the additive manufacturing program, Mike Littrell, owner and president of C.idease, decided to explore the possibility of powder laser manufacturing (SLS) production. He discovered "a change that can absolutely disrupt the market."

Already used to the operation of FDM machines, President Mike Littrell wants an SLS machine that everyone can use in the company. The president found 3D SYSTEMS's all-digital 3D printer, which can lead him to surpass all front-end software competition.

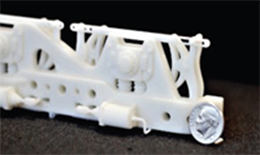

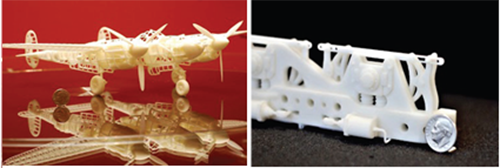

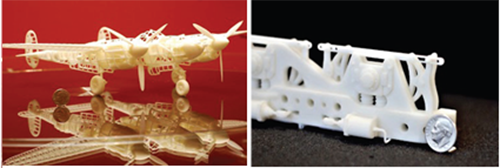

Before having its own system, C.ideas cooperated with other departments to meet the production requirements of SLS and the previous obstacles faced by multiple geometric feasibility restrictions. President Mike Littrell operated the new sPro 60 HD HS3D printer for the first time and tested the various difficulties encountered previously, and said, "This machine is incredible." He was surprised not only by the versatility of production and the speed of printing, but also the product. The superior quality.

He immediately noticed that he only needed very little post-processing to achieve an incredible smooth surface flatness, which not only exceeded his expectations for all the details and features, but he had thought it would not even happen in SLS.

We have been able to produce parts that I told me many years ago that they could not be produced in SLS. He far exceeds our imagination. Actually use it and the speed of production part is unprecedented.

Because SLS is faster in production and in many cases the working cost is cheaper than FDM.

President Mike Littrell said that he clearly sees his company becoming the SLS and FDM faction, especially the growing trend of additive manufacturing. "President Mike Littrell said the quality is very good." "I can't honestly face myself without this machine in this process." For me, this all-digital, high-resolution, high-speed machine is definitely this. The next reasonable direction of the manufacturing process can achieve stunning quality appearance and excellent details.

![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158