![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158

![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158

PRODUCT LIST

|

|

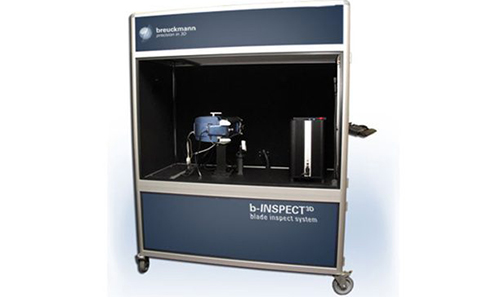

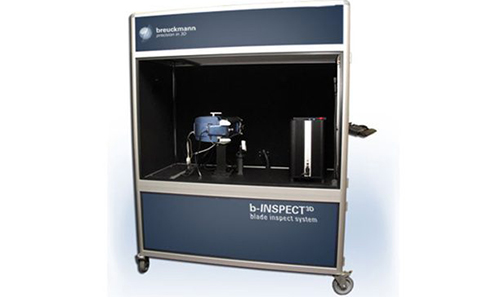

When the b-INSPECT 3D scanner scans, it scans the entire surface instead of individual points. This feature allows it to measure more complex curved surfaces with extremely high accuracy. No matter what the material of the part is, casting or composite material; and no matter how the surface shape is obtained, whether it is forging, milling or polishing, the equipment can obtain extremely accurate three-dimensional data. The entire scanning process does not need to touch the workpiece, so even for those easily deformable and fragile workpieces, such as wax workpieces or ceramic workpieces, the three-dimensional data of the surface can be easily and quickly obtained.

B-INSPECT 3D scanner scans the entire surface instead of individual points when scanning. This feature makes it possible to measure more complex curved surfaces with extremely high accuracy. No matter what the material of the part is, casting or composite material; and no matter how the surface shape is obtained, whether it is forging, milling or polishing, the equipment can obtain extremely accurate three-dimensional data. The entire scanning process does not need to touch the workpiece, so even for those easily deformable and fragile workpieces, such as wax workpieces or ceramic workpieces, three-dimensional data of the surface can be obtained easily and quickly. Equipped with Brouckmann's high-end scanner stereoSCAN 3D-HE and the integrated measurement system of the robot can complete the measurement of the complete geometry of the workpiece in a short time. Even for complex workpieces, the three-dimensional data of the surface can be accurately obtained without any pre-processing, such as spraying reflective powder or developer. The robot can automatically and completely obtain the three-dimensional data of the relevant range. The system is shockproof and dustproof, and can accurately obtain three-dimensional data on the surface of the workpiece in harsh manufacturing environments such as workshops and factories. Fast speed and high precision Compared with traditional measuring instruments, the optical coordinate measuring system can quickly complete the detection of workpieces on the basis of breaking through the double contradiction of time constraints and manpower requirements. With b-INSPECT 3D scanner turbine blades, it only takes 2 to 4 minutes. The speed of digitization has been greatly improved. The equipment is characterized by high scanning accuracy, fast speed, and large amount of data acquisition. Evaluate measurement data Through the simple and easy-to-understand operation interface, the operation of the equipment can be realized. The equipment does not have high requirements for the working environment. Whether it is an office, a workshop, or a factory, the equipment can be used to obtain three-dimensional data on the surface of the workpiece. After scanning, the automatically generated data will be automatically compared with the original CAD design data and a corresponding evaluation report will be created, which can be used as a theoretical basis for the adjustment of the later casting process. Back-projecting the determined offset after the measurement to the measured object is beneficial to the overall analysis of the measurement result and also provides a direction for the optimization of the manufacturing process. There is no doubt that the scanned data is a powerful guarantee for the improvement of production efficiency and product quality. |

Copyright © Shenzhen Airboat Technology Co., Ltd. All rights reserved 【Backstage management】