3D Printing-Doll Forming Application

1. Application Overview

3D printing (RP rapid prototyping) is to use stacking technology to output your three-dimensional image files into real 3D models, such as dolls, toys, etc...

2. System Overview

The ProJet HD35103D printer, a new office-specific model developed by 3D Systems, is just up to this task. As long as you convert your 3D entity files to STL format, and then use HD3510 for physical molding, you can not only save manual model making Time and expense will greatly enhance the competitiveness of products

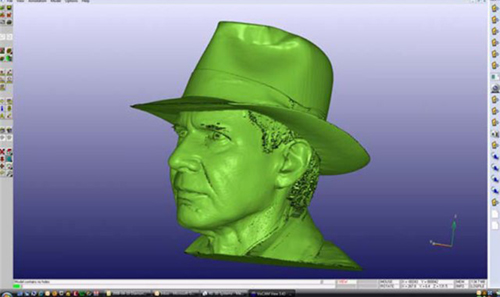

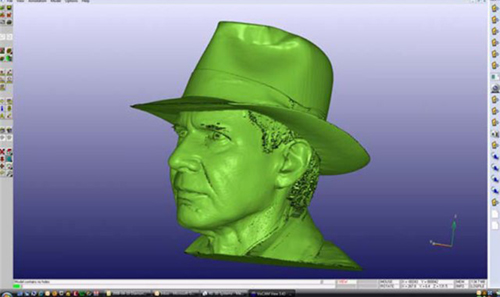

3. Great Adventurer-Forever Legendary Hero

The legendary hero Indiana Jones (played by Harrison Ford) is the greatest adventurer on the silver screen. Among them, Indiana Jones was in the best box office "Indiana Jones". In order to save the world from the poison of the Nazis, he led his father Henry. Dr. Jones was taken away (played by Sean Connery) because his diary recorded the Holy Grail data and related maps. According to legend, as long as you drink water in the Holy Grail, you can live forever, which is exactly what the Nazis wanted. Indiana. Jones must chase all the way to Venice and even the Syrian desert to save the Holy Grail and his father.

4. Product application-unlimited business opportunities in the toy industry

Such a splendid movie plot made toy manufacturers think of business opportunities. They used a 3D printer (RP rapid prototyping) system to produce four Indiana Jones movies, "Ark of the Ark", "Legend of the Devil's Palace" and "Jihad" series . After printing the model of Indiana Jones accurately and quickly, it was presented to the film company officials for review.

The toy company said: "It looks very detailed and realistic after molding, so we are happy to use it, and as the main system for producing toy prototypes." Compared with the traditional production method using clay sculpture, we use a rapid prototype 3D printing system. Speed up the production process.

"Technology is here"

Said McHnch, president of PCS Inc., a well-known American toy developer. "As long as there are 3D graphics files and you own this set of equipment, you will get the model within 24 hours." The quality of the model making and the fast forming speed surprised his customers. "Customers don't believe that the high-precision and fast output mode can perform so well," Hanqi said: "Customers see the model as if you look at Indiana Jones himself, you can see his personal characteristics at a glance."

5. High-precision and productive ProJet? HD 3510 3D printer

"Since we purchased this system, the ProJet? 3D printer has never stopped working. We have continuously used these two precision modes to form high-resolution and ultra-high-resolution based on customer needs." Hanqi said: "When our customers look at the finished product, they say, "Oh my God! They are really very meticulous, just like me."

3D Systems' new ProJet? HD3510 RP 3D printer device is a model that can select double precision mode. With sufficient molding range, larger and more models can be made, and the advantages of unmanned production and high-precision stacking cannot be replaced by other equipment. Including concept development, design inspection, and modeling output are all the advantages of 3D printing. Manufacturers can even turn the printed model into a silicone mold or directly use dewaxing casting for mass production.

![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158![]() Tel:+86 135 7086 9158

Tel:+86 135 7086 9158

5. High-precision and productive ProJet? HD 3510 3D printer

5. High-precision and productive ProJet? HD 3510 3D printer 3D Systems' new ProJet? HD3510 RP 3D printer device is a model that can select double precision mode. With sufficient molding range, larger and more models can be made, and the advantages of unmanned production and high-precision stacking cannot be replaced by other equipment. Including concept development, design inspection, and modeling output are all the advantages of 3D printing. Manufacturers can even turn the printed model into a silicone mold or directly use dewaxing casting for mass production.

3D Systems' new ProJet? HD3510 RP 3D printer device is a model that can select double precision mode. With sufficient molding range, larger and more models can be made, and the advantages of unmanned production and high-precision stacking cannot be replaced by other equipment. Including concept development, design inspection, and modeling output are all the advantages of 3D printing. Manufacturers can even turn the printed model into a silicone mold or directly use dewaxing casting for mass production.